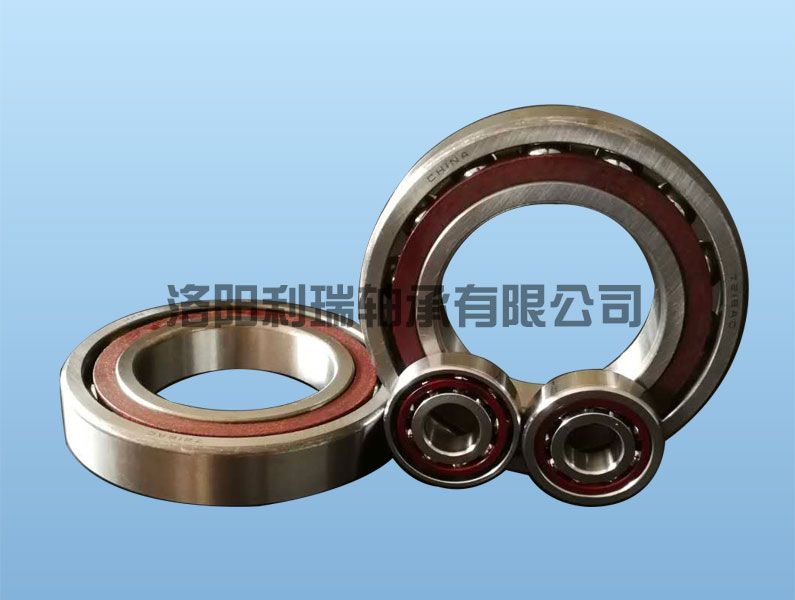

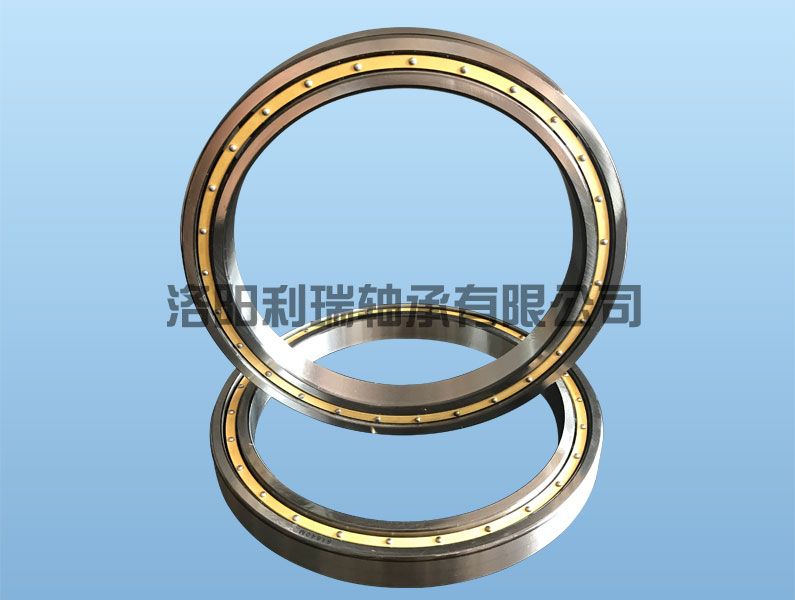

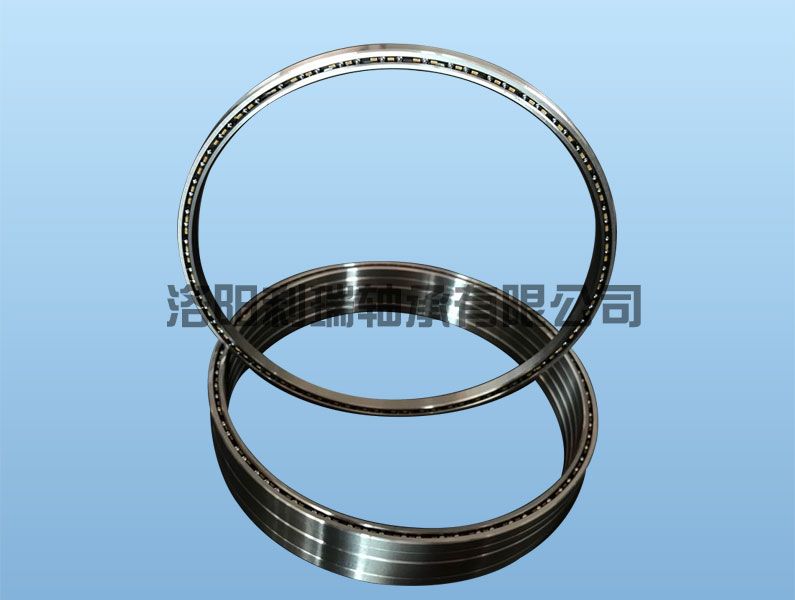

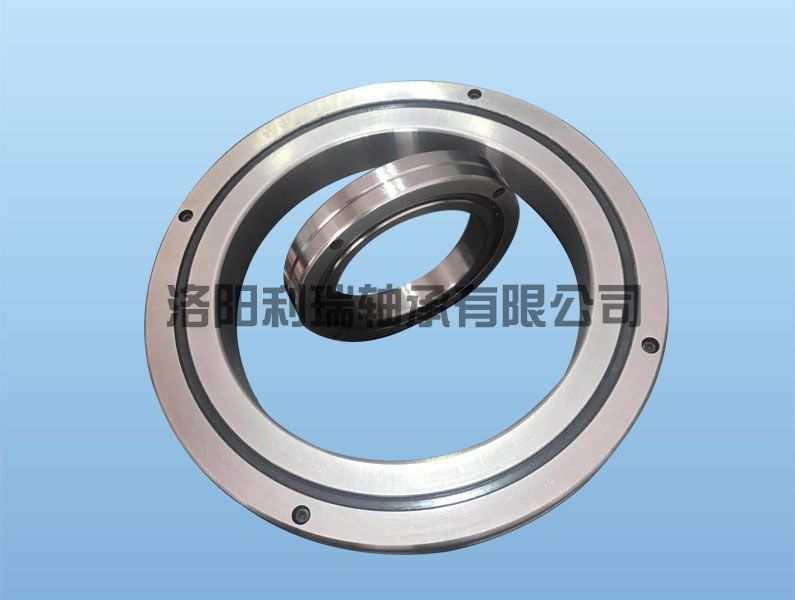

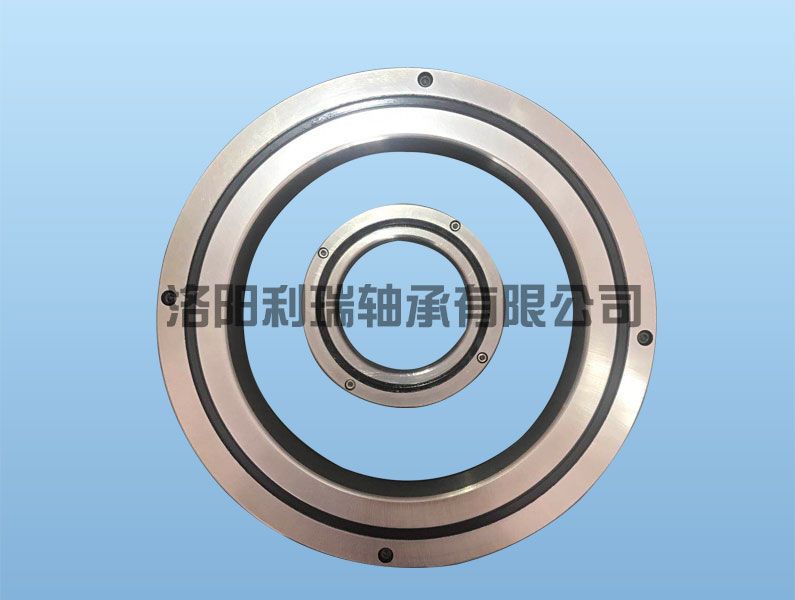

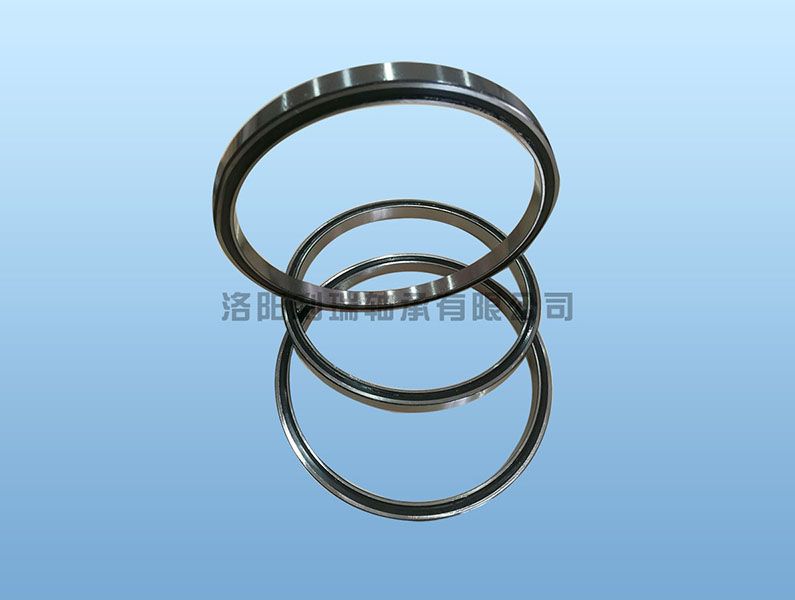

Precise thin wall bearing with constant section

About us

Strong research and development, we do everything in detail

Luoyang Lirui Bearing Co., Ltd. has professional design, research and development of high-precision, high-performance, high-quality bearing products, precision bearings, replacement of imported bearings and special bearings

Military technology, the choice of the world, get customer praise

Thin wall bearing has a wide range of application space, it can also save installation space, reduce weight, significantly reduce friction, and provide good rotation accuracy. The use of Thin-walled bearing can reduce the external size of the design. The product has the advantages of high rigidity, small cross-section, good bearing performance and various cross-section sizes, and can solve many conventional problems

Luoyang Lirui Bearing Co., Ltd, located on the ancient capital city Luoyang which is the production base for bearing, is a new-high technology corporation with the integration of design, research and development, manufacturing. Our company, based not only on the development of China’s bearing, but also the global perspective has first-class team of bearing experts and engineers, the domestic first-class CNC grinding, automatic equipment, and large-scale sophisticated equipment, all of these guarantee our bearing with high precision and stability.Our company has been found in 2008 since the establishment, we inherit "honest and trustworthy, the user orientated", adhere to high quality pre-sales technical support, superior product quality coupled with excellent after-sale service to serve every customer. We are specialized in the design, research and production to various non standard bearing, imported substitution bearing and special bearing, which are widely applied to aerospace, precision instruments, textile, precision lathe, port, mining, medical treatment, coal, cement, oil drilling, wind power generation, industrial robots, defense industry and other fields. Our products are exported to, Canada, Germany, the United States, Austria, Italy, Japan, South Korea, Singapore, Pakistan, Thailand, Malaysia and other countries.We have got ISO9001:2000 certificate, as it is represented in “Quality Guideline”, Lirui bearing focus on comprehensive quality management, and take it as a sustained effort to improve customer satisfaction. These require our team including senior management take on-the-job training and further education. At the meantime, it is necessary to establish full assessment to ensure this goes smoothly in this area. The company gradually forms a stable country and worldwide sales network. Each product reflects constant pursuit of excellence of Lirui employees, and serves our customers by qualified products and business philosophy of "innovation, integrity and pragmatic, development". Creating value for customers and guarantee satisfaction to the customers are our principle, thus, we sincerely welcome our friends from all over the world come to discuss, exchange and cooperation, and with our joint hands to create a bright future.